Palm oil is one of the most versatile ingredients in the world, found in everything from shampoo and toothpaste to cakes and coffee creamer.

But how is palm oil made?

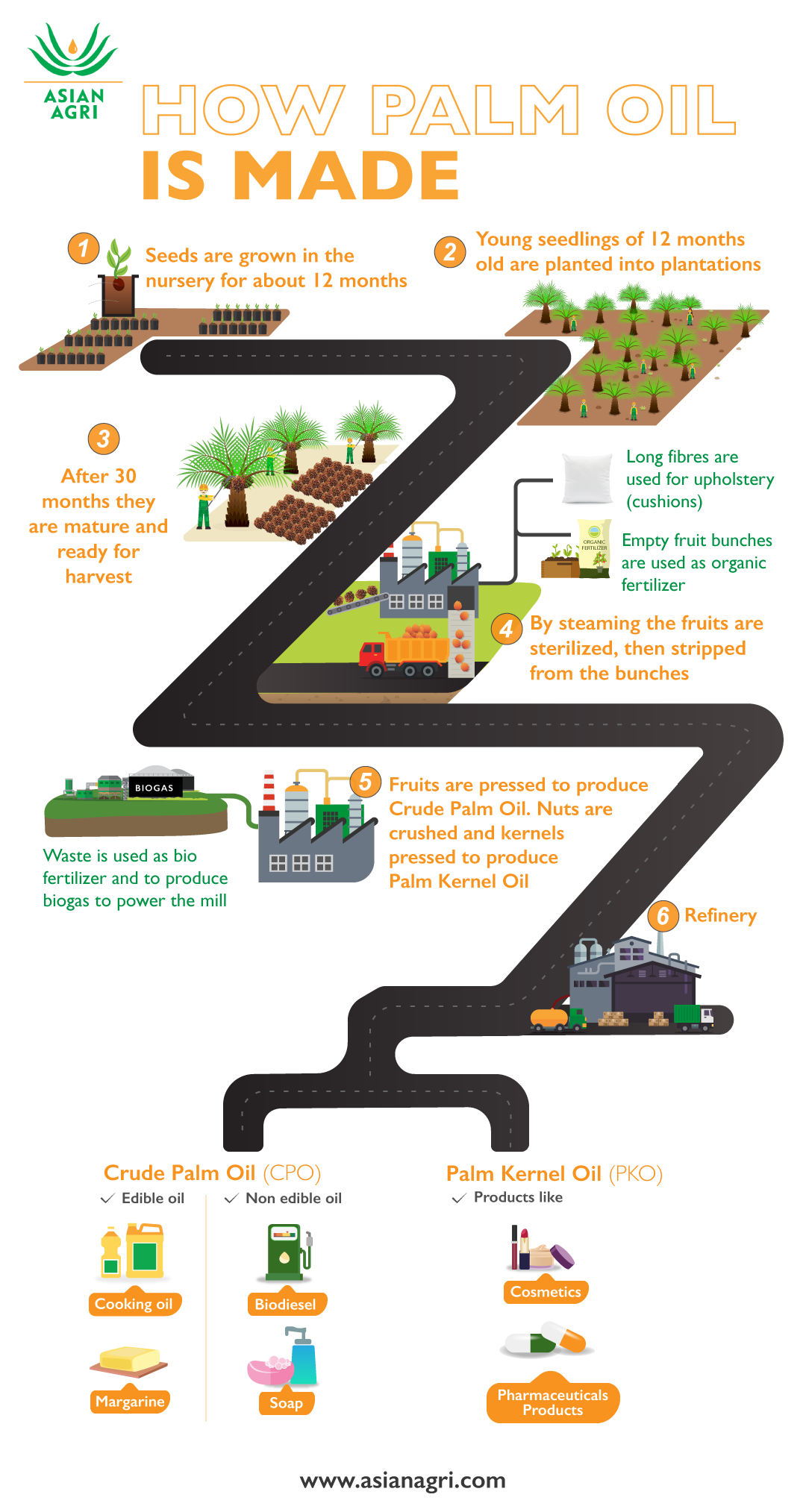

Palm oil production begins with palm oil seeds. As oil palms have a productive life of 25-30 years, the choice of seeds will impact production for decades to come. Asian Agri has developed its own Topaz seeds, which produce higher yields and are more resistant to pests than regular oil palms, increasing productivity of oil palm plantations.

The seeds are planted in a nursery where they receive daily watering and upkeep for the first eight months of their life, before being transplanted to the plantations.

In the plantations the trees are watered and treated with fertiliser as needed while they grow. After 30 months they are considered mature and are ready for their first harvest, a process that will be repeated every 7-10 days.

Palm oil fruit grow in dense bunches known as Fresh Fruit Bunches (FFB). To harvest the FFB, the harvester uses a long sickle to remove it from the palm tree. FFB which are ready to be harvested can be easily identified due to the bright red-orange colour of their palm fruit.

Processing at the mill

The harvested FFB are transported in trucks from the plantations to the mills, where they are sterilised using steam. This prepares the FFB for stripping, which will remove the palm fruit from the bunch, and also deactivates any enzymes which may cause the FFB to deteriorate in quality.

Once the FFB has been stripped, any waste is reused. The long fibres in the stalks can be used to make mattresses and car seat cushions, while the remaining empty fruit bunches are returned to the soil where they help retain moisture before serving as fertiliser when they eventually decompose.

Infographic – How Palm Oil Is Made

After being stripped from the FFB, the palm fruit is processed into two main products: Crude Palm Oil (CPO), which is extracted from the mesocarp or flesh of the fruit, and Palm Kernel Oil (PKO), which comes from the hard seed in the centre.

The first step is to press the fruit, which squeezes CPO from its mesocarp. The oil is then screened and clarified to ensure it is free from contamination, and dried to meet standard CPO specifications.

Next the CPO is transferred to a refinery where it is processed into edible oils (cooking oil, cream and margarine), oleo chemicals (used in detergents and lubricants), biodiesel (fuel) and lauric acids (used in cosmetics and soaps).

Meanwhile, a ‘cake’ comprising a mix of mesocarp fibre and seed is left behind in the press. This press cake is fed into the depericarper station, which separates the mesocarp fibre and seed.

The mesocarp fibre is used as biofuel in the palm oil mill’s boilers, which produce steam to drive turbines to power the mill.

The remaining palm seeds, also known as kernels, are cracked and deshelled. The shells are taken away to be sold as biofuel, while the kernels undergo further crushing to produce crude Palm Kernel Oil (PKO) and Palm Kernel Expeller (PKE).

The crude PKO also undergoes a refining process before it is used in the making of food products such as non-dairy creams and ice cream, while the leftover PKE is generally used to make animal feed.

Recycling leftovers

At Asian Agri, leftover waste water from the palm oil production process – called Palm Oil Mill Effluent (POME) – is also recycled, either as fertilizer or as fuel for bio digesters which convert it into biogas. Currently Asian Agri has seven biogas plants, which use the resulting natural gas to power the mill and operations, as well as provide electricity to neighbouring communities.

Asian Agri uses a circular production process, minimising waste and maximising efficiency, a key requirement of certification bodies such as the Roundtable on Sustainable Palm Oil (RSPO). That allows for higher productivity and a lower environmental impact, creating products that are used by millions of people around the world every day in a sustainable manner.